News

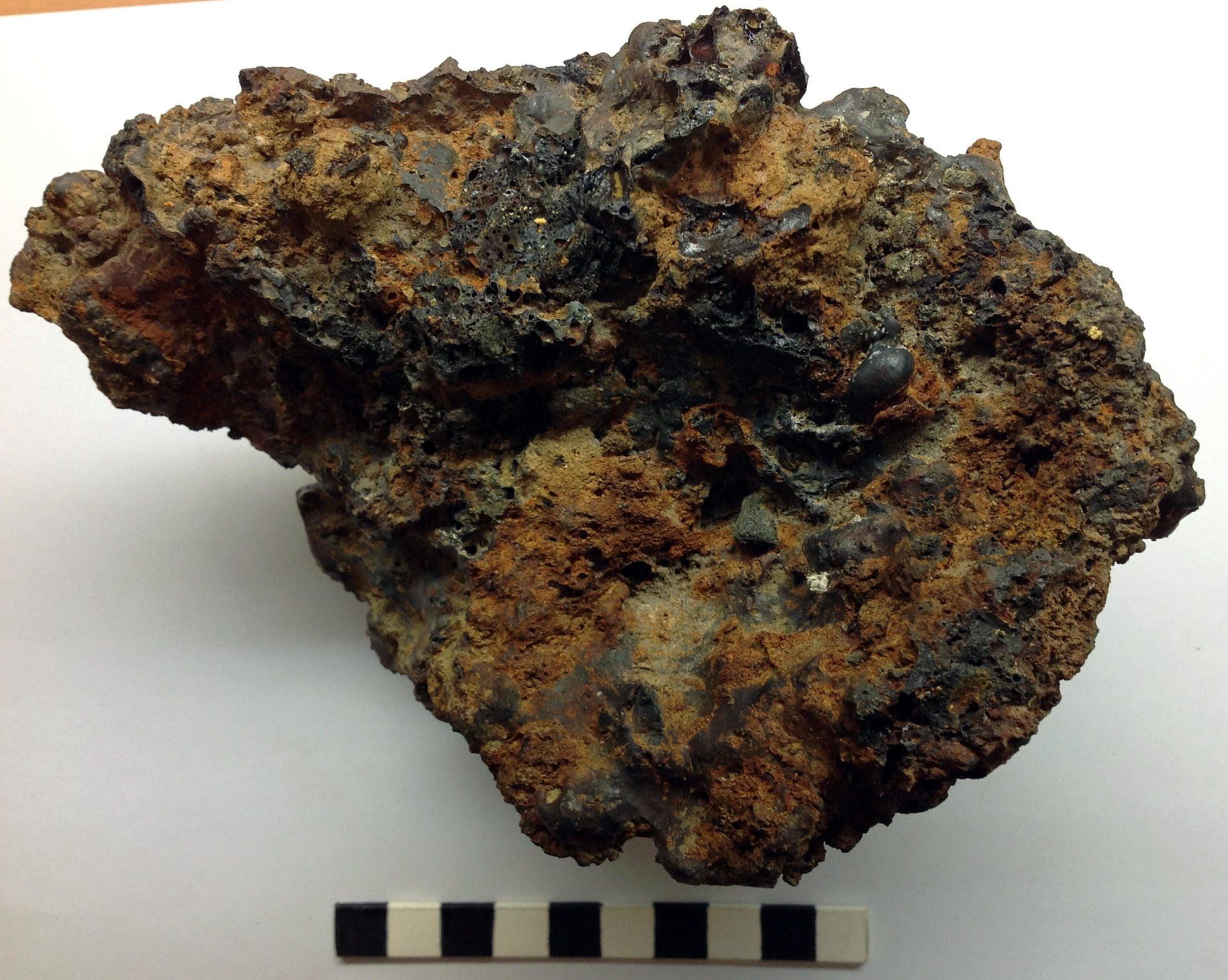

The slag material found at the archaeological site Rijselseweg in Ypres, Belgium consists of smithing slag, hammerscale and parts of the forge. The characteristics of the remains show that coal was used in a raised forge which probably stood nearby. Although the use of coal is quite probable for a late-medieval site like this, there aren't many other archaeological sites known where this is the case. Both iron and coal would have arrived at the site through trade with for instance Sweden and England. Since this part of medieval Ypres was known for its textile production, it is quite possible that the smith produced iron goods needed directly (scissors) or indirectly (horseshoes for transport) in the textile industry.

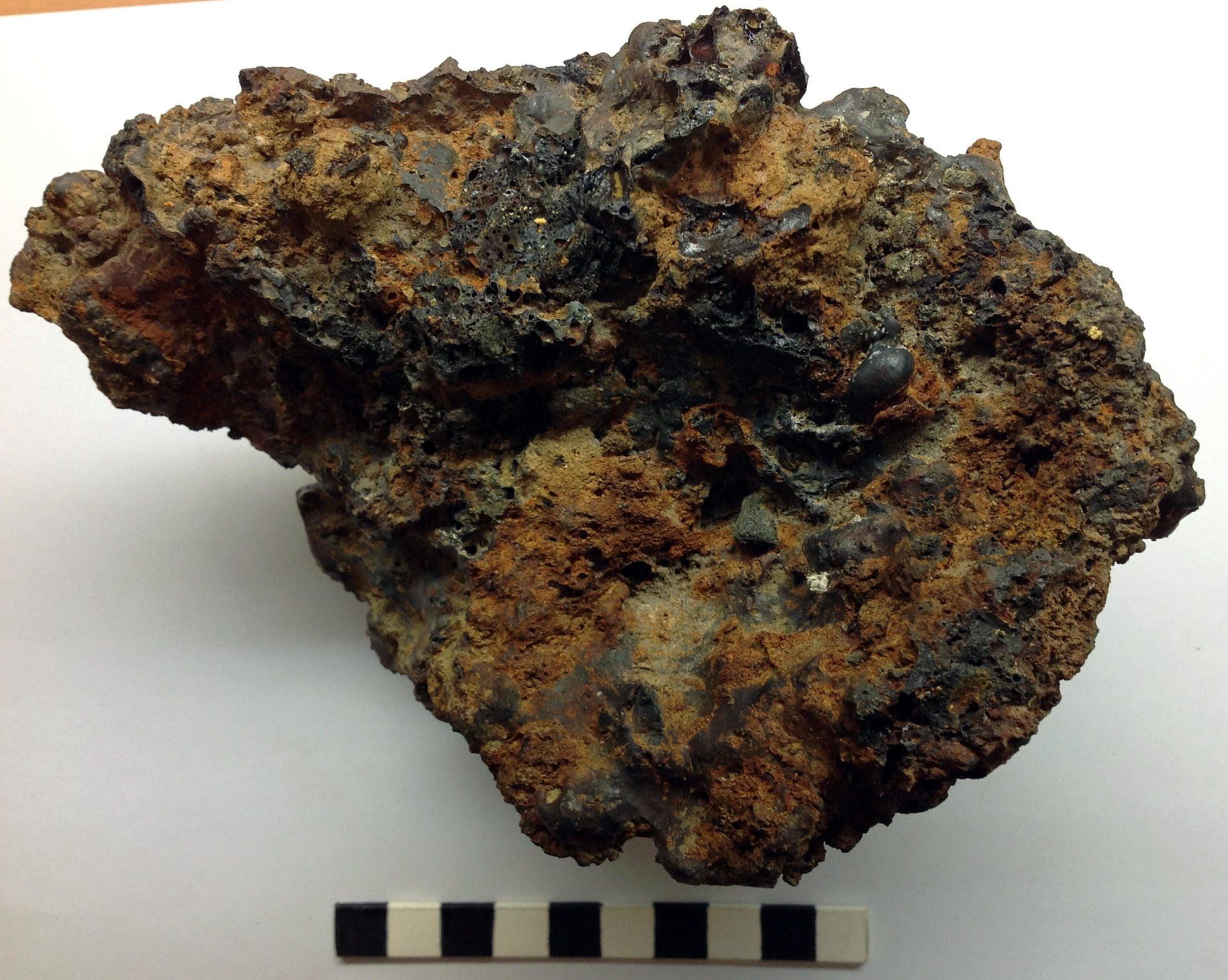

Three types of slag were recognised at the Waalbandijk-site: smithing slag, slag from copper-alloy working and coal slag. Based on context information, all slag dates from the Roman period (1st-3rd century AD). It can be concluded from the smithing slag that iron was worked in a raised heartth; typical in Roman contexts. Less typical is the use of both charcoal and coal as fuel. There is also evidence for the melting and/or smithing of copper-alloy objects. Possibly the same hearth as for the iron smithing was used, but this is not mandatory. Lastly, coal slag is the result of using coal as fuel for heathing and/or other craft activities. In the last case, fuel and the to be heated materials were seperated so a pure coal slag formed.

The slag material found at the archaeological site Rijselseweg in Ypres, Belgium consists of smithing slag, hammerscale and parts of the forge. The characteristics of the remains show that coal was used in a raised forge which probably stood nearby. Although the use of coal is quite probable for a late-medieval site like this, there aren't many other archaeological sites known where this is the case. Both iron and coal would have arrived at the site through trade with for instance Sweden and England. Since this part of medieval Ypres was known for its textile production, it is quite possible that the smith produced iron goods needed directly (scissors) or indirectly (horseshoes for transport) in the textile industry.

Three types of slag were recognised at the Waalbandijk-site: smithing slag, slag from copper-alloy working and coal slag. Based on context information, all slag dates from the Roman period (1st-3rd century AD). It can be concluded from the smithing slag that iron was worked in a raised heartth; typical in Roman contexts. Less typical is the use of both charcoal and coal as fuel. There is also evidence for the melting and/or smithing of copper-alloy objects. Possibly the same hearth as for the iron smithing was used, but this is not mandatory. Lastly, coal slag is the result of using coal as fuel for heathing and/or other craft activities. In the last case, fuel and the to be heated materials were seperated so a pure coal slag formed.